| | LRK Home | | Bio Info | | Krash Khronicles | | LAROKE | |

| | BettyLou | | BillyBob's Garage | | Rat Patrol | | Deerslayer | | Elvira | |

| | Land of the Free and Home of the Brave | |

| | Keppylou's Art | | WWI Soldier's Diary | |

BillyBob Work-in-Progress Log

![]()

TRUCK LINKS including vendor sites for old parts, custom parts, and tools as well as sites for classic car and truck organizations

STORE Operating in association with Amazon.com, books, recordings and tools can be purchased.

PLANNING for the restoration including project schedule and cost estimates.

![]()

WORK-IN-PROGRESS is the restoration of parts of BillyBob that I can accomplish without a garage.

PRE-RESTORATION includes log entries of minor repairs and and adventures between time of purchase and the time when I started restoration, a piece at a time.

JR'S KORNER JR's Korner is the history of BillyBob before I got him authored by my brother, Wm. C. Kephart.

![]()

BILLYBOB MAINTENANCE Ever changing detailing, oil change, lube, etc. maintenance routines specifically developed for BillyBob, including required tools, materials and procedures.

STEALTH SHOP Urban residence design with large integrated shop and separate living quarters for a relative or renter.

![]()

You will need the Adobe Acrobat browser plugin to view these wiring diagrams which are in the PDF file format. This format allows zooming and panning. If you don't have this plugin, it can be downloaded and installed (free) from the Adobe site. The button below will take you there.

BILLYBOB WIRING DIAGRAM Here's the wiring diagram updated with the temporary light switch jumper, dome light circuit and lighter circuit.

UPDATED BILLYBOB WIRING DIAGRAM Here's the updated wiring diagram again, now with the new replacement headlight switch in place, new battery cables, and new turn signal re-wiring.

25. Nervous Breakdown Red Ducks

Wuz gonna call this log entry "Nervous Breakdown Redux" but I'm boycotting the French right now and even tho' "redux" is latin, it sounds suspiciously Frenchie to the unrepentant hillbilly in me. Now before my Cajun friend "Swampcat", and other Internet stovebolter readers of French descent get riled up, I am decended, in part, from a French great grandfather Ross on my Mother's side who came to Pennsylvania by way of Canada. I submit that many of these ancestors braved the new world frontier because they were fed up with the home country too! Swampcat called me "Herr Kephart" the last time I wrote against the French . . . I'm only glad my last name isn't Lipp.

At any rate, this log entry recovers some ground I've already gone over (headlight switch, parking lamps, battery cables and turn signals) and some new items I'm visiting for the first time (ballast resistor, ignition switch, dome light and cigarette lighter).

October

24th 2002 Two spare

ballast resistors (#EL809) and a generic ignition switch with lock

cylinder and two keys (#IGS36) arrived from American

Classic Truck Parts today.

October

24th 2002 Two spare

ballast resistors (#EL809) and a generic ignition switch with lock

cylinder and two keys (#IGS36) arrived from American

Classic Truck Parts today.

December

7th 2002 Pearl Harbor

Day. Good working weather. Took off the old ballast resistor and put it

in the glove compartment as a spare in case the new ballast resistor

turns out to be defective. Drilled a new 9/64" mounting hole lower and

to the left of the old mounting hole (flatter area of the firewall).

Installed the new ballast resistor with the supplied plated,

self-tapping cap screw. Attached the coil and wiring harness wires with

the existing blade type connectors.

December

7th 2002 Pearl Harbor

Day. Good working weather. Took off the old ballast resistor and put it

in the glove compartment as a spare in case the new ballast resistor

turns out to be defective. Drilled a new 9/64" mounting hole lower and

to the left of the old mounting hole (flatter area of the firewall).

Installed the new ballast resistor with the supplied plated,

self-tapping cap screw. Attached the coil and wiring harness wires with

the existing blade type connectors.

Wasn't supposed to rain but it started to by mid-morning. I'm also detailing the parking brake cable connections today (gettin' rid of the rust starting to creep back on things I've already fixed) so, I went inside to tin-zinc plate bolts and other hardware while I waited out the weather. After the rain stopped, the ignition switch was replaced with the new generic ignition switch. There is not much improvement here 'cept that the switch positions are solid "clicks" (I now know I am at accessory, off, or ignition settings) whereas the old generic switch was kinda loosey-goosey. I also now have a spare ignition key. The old switch and key goes into the spare parts inventory.

February

8th 2003 Keepin' it

light today. The boss's wife decreed sometime back that the office

needed new carpet. The rest of us resisted as long as we could. The

carpet arrived this week and the Krash Lab will be in disarray for the

next three or four weekends. The installer needs BillyBob's shadetree

garage area to cut the carpet ~!@#$%

Decided to install a new dome lamp assembly I got from Chevy

Duty a couple of months ago.

February

8th 2003 Keepin' it

light today. The boss's wife decreed sometime back that the office

needed new carpet. The rest of us resisted as long as we could. The

carpet arrived this week and the Krash Lab will be in disarray for the

next three or four weekends. The installer needs BillyBob's shadetree

garage area to cut the carpet ~!@#$%

Decided to install a new dome lamp assembly I got from Chevy

Duty a couple of months ago.

This

thing looks pretty close to the original and does not look as if it

will have to be "beaten into shape" as some other repro parts have to

be. It has a bullet connector and I was supprised to find that the old

wiring has a bullet receptacle when I removed the old assembly. Did not

feel like pulling new wire so it was connected to the old and tested.

Good! Now I can read a map at night (providing I have my reading

glasses with me).

This

thing looks pretty close to the original and does not look as if it

will have to be "beaten into shape" as some other repro parts have to

be. It has a bullet connector and I was supprised to find that the old

wiring has a bullet receptacle when I removed the old assembly. Did not

feel like pulling new wire so it was connected to the old and tested.

Good! Now I can read a map at night (providing I have my reading

glasses with me).

At

the same time I purchased the dome light, I got a new 54-55 1st

Series cigarette lighter (with the correct knob). This accessory was

connected to the battery terminal on the ignition switch with 14 gauge

wire. I had to take out the glove box cardboard to remove the old

corroded lighter. The glove box fell apart in my hands. Not gonna

replace the cardboard until I'm finished in this area of the dashboard

'cause the access is so nice with it out.

At

the same time I purchased the dome light, I got a new 54-55 1st

Series cigarette lighter (with the correct knob). This accessory was

connected to the battery terminal on the ignition switch with 14 gauge

wire. I had to take out the glove box cardboard to remove the old

corroded lighter. The glove box fell apart in my hands. Not gonna

replace the cardboard until I'm finished in this area of the dashboard

'cause the access is so nice with it out.

Been havin' a few problems with the lights . . . Sometimes the instrument lights and the parking lights won't work. Two times I thought I detected something burning too. Pulled out the light switch. No detectable burns but the ~!@#$%darn rheostat ceramic is crumbling! I moved the jumper from the second rheostat terminal to the first rheostat terminal to bypass it. Now I have instrument panel and parking lights again . . . At least today I have. Look's like the search for a good headlight switch is not over.

March

26th 2003 'Nother

parking lamp lense fell out on the way to work today. As before, the

area around the screw boss had fractured. The screws and bits of the

plastic around them remained in place. The last time this happened I

went up to the warehouse and dug the original parking lamps out of the

spare parts. I think I've discovered why the lenses keep breaking. The

gaskets behind the lenses are cork, not rubber. When they get wet they

swell up. If you snug up the screws that came with the new lamp units

enough to keep them from backing out, the lenses will fracture when the

cork gaskets get wet. The new screws are just machine screws threaded

their full length. When I looked at the old screws, the light bulb came

on behind my eyes. The old screws are threaded less than a quarter

inch, then there is a shoulder that continues up to the screw head. The

old screws can be tightened and still leave expansion room for the

lenses. Once again, the off-shore remanufacturers did not go the full

distance to provide a quality part ~!@#$%^

I hope this problem is solved now.

March

26th 2003 'Nother

parking lamp lense fell out on the way to work today. As before, the

area around the screw boss had fractured. The screws and bits of the

plastic around them remained in place. The last time this happened I

went up to the warehouse and dug the original parking lamps out of the

spare parts. I think I've discovered why the lenses keep breaking. The

gaskets behind the lenses are cork, not rubber. When they get wet they

swell up. If you snug up the screws that came with the new lamp units

enough to keep them from backing out, the lenses will fracture when the

cork gaskets get wet. The new screws are just machine screws threaded

their full length. When I looked at the old screws, the light bulb came

on behind my eyes. The old screws are threaded less than a quarter

inch, then there is a shoulder that continues up to the screw head. The

old screws can be tightened and still leave expansion room for the

lenses. Once again, the off-shore remanufacturers did not go the full

distance to provide a quality part ~!@#$%^

I hope this problem is solved now.

May 18th 2003 I've been trying to get the unknown 12v voltage regulator off the driver side inner fender for some time now but one of the mounting machine screw/hex nuts is hopelessly rusted. I had BillyBob's front wheels off today to work inside the wheelwell. I finally quit pussy-footin' around an' used the air-powered cut-off wheel to cut the hex nut off from below. I'm still out of luck tho' . . . The voltage regulator does not have any part numbers or brand names on it anywhere, inside, outside, top or bottom. This thing is as nondescript as they come.

June

3rd 2003 Received an

order from Jeff McCoy at Bowtie Bits yesterday. Two items

that I haven't seen anywhere else yet: a repop 54-55 horn button and a

replacement headlight switch with the correct 54-55 1st series knob on

it. I messed up BillyBob's original horn button some when I was trying

to paint it. I will have another go at repairing it somewhere down the

line. I have a similar replacement headlight switch in inventory that I

got from Chevy Duty but it has this butt ugly little tan knob on it

that doesn't look like anything else on the dashboard so I designated

it for emergency use only.

June

3rd 2003 Received an

order from Jeff McCoy at Bowtie Bits yesterday. Two items

that I haven't seen anywhere else yet: a repop 54-55 horn button and a

replacement headlight switch with the correct 54-55 1st series knob on

it. I messed up BillyBob's original horn button some when I was trying

to paint it. I will have another go at repairing it somewhere down the

line. I have a similar replacement headlight switch in inventory that I

got from Chevy Duty but it has this butt ugly little tan knob on it

that doesn't look like anything else on the dashboard so I designated

it for emergency use only.

June

7th 2003 Wanted to

replace a water pump today but I've got to paint a pulley and fanblade

first and the rainy conditions aren't conducive to painting. While

waiting for it to dry up, I decided to install the replacement

headlight switch since it's slightly drier inside the truck. The new

replacement switch has fewer terminals than the original so some

brainstorming was required. With the help of BillyBob's wiring diagram

and the labels on the new switch I was able to get everything

connected. Basically, items that had a fuse and/or switch (turn

signals, brake light) was connected to the hot "BAT" terminal or the

hot "Aux" terminal (dome light). Rest of the wires had corresponding

terminals on the new switch to connect to. The new switch has the same

tang to locate it properly behind the dashboard, then the original

ferrule could be slipped over the knob shaft and screwed down tight.

Finally the new plastic 54-55 knob could be screwed on the end of the

shaft and tightened (by gripping the shaft with pliers to keep it from

twisting). Works good! Then BillyBob's wiring diagram was updated once

again.

June

7th 2003 Wanted to

replace a water pump today but I've got to paint a pulley and fanblade

first and the rainy conditions aren't conducive to painting. While

waiting for it to dry up, I decided to install the replacement

headlight switch since it's slightly drier inside the truck. The new

replacement switch has fewer terminals than the original so some

brainstorming was required. With the help of BillyBob's wiring diagram

and the labels on the new switch I was able to get everything

connected. Basically, items that had a fuse and/or switch (turn

signals, brake light) was connected to the hot "BAT" terminal or the

hot "Aux" terminal (dome light). Rest of the wires had corresponding

terminals on the new switch to connect to. The new switch has the same

tang to locate it properly behind the dashboard, then the original

ferrule could be slipped over the knob shaft and screwed down tight.

Finally the new plastic 54-55 knob could be screwed on the end of the

shaft and tightened (by gripping the shaft with pliers to keep it from

twisting). Works good! Then BillyBob's wiring diagram was updated once

again.

June 21st 2003 Florida's rainy season this year is, well, rainy. Today, so far, I'm getting an occasional misting rain but the forecast is for deluge. Started out with monthly maintenance. I am really butterfingered today . . . dropin' everything. Wrenches, bolts, radiator cap. The list is endless. I carefully drained the remaining drops of gear oil from one container into another half full container, then knocked them both over and lost more gear oil on the shed floor than I'd saved! Turned the air blue with foul language for a minute or two at that point.

Back

when I first started addressing BillyBob's electrical system, I knew a

lot less about electrical issues and I still don't know much. At that

time I replaced the battery cables with a red #2 wire positive cable

and a black #6 ground cable. With the help of Randy Rundell's book and

fellow oletrucks maillist member Bill Hanlon, I decided to eventually

replace the #6 cable with a #2 cable to match the red positive cable.

To those ends, I recently purchased Eastwood's Battery Cable and

Connector Kit (#25080). This kit contains an eight foot length of #2

cable (just enuf if you're careful), two battery terminal compression

connectors and two ring compression connectors, and two black and two

red lengths of heat shrink insulation. Also got Eastwood's Cable Cutter

pliers (#25066) which aren't in the picture. The ring connectors are a

bit big for the starter terminal and ground bolt where these connectors

attach so I got a couple of smaller copper crimp connectors at a local

FLAPS.

Back

when I first started addressing BillyBob's electrical system, I knew a

lot less about electrical issues and I still don't know much. At that

time I replaced the battery cables with a red #2 wire positive cable

and a black #6 ground cable. With the help of Randy Rundell's book and

fellow oletrucks maillist member Bill Hanlon, I decided to eventually

replace the #6 cable with a #2 cable to match the red positive cable.

To those ends, I recently purchased Eastwood's Battery Cable and

Connector Kit (#25080). This kit contains an eight foot length of #2

cable (just enuf if you're careful), two battery terminal compression

connectors and two ring compression connectors, and two black and two

red lengths of heat shrink insulation. Also got Eastwood's Cable Cutter

pliers (#25066) which aren't in the picture. The ring connectors are a

bit big for the starter terminal and ground bolt where these connectors

attach so I got a couple of smaller copper crimp connectors at a local

FLAPS.

Used

some of the cable to reroute to a secondary cut-off switch, then

proceeded to make a new ground cable. Removed the old #6 ground cable

and used it to measure the length for the new #2 cable. Stripped an

inch of insulation off one end and crimped the FLAPS copper ring

connector on it. Then tried to solder the connection with my small

computer tool kit soldering iron. About the time I realized it was too

small for the job, the soldering iron cord got caught on something and

kept the soldering iron from going any further in the direction my hand

was going, and my fingers went down to the the hot end of the iron

causing some of my smoke to escape my body. ~!@#$%

Good news is that the the iron wasn't very hot from it's efforts to

heat up the cable and connector and that a callosed part of my hand

only made brief contact. A couple of my fingerprints look like the

sepia woodgrain in a kid's woodburning kit but that's about it. I don't

even think I'm gonna get a blister. Enuf of this. Pulled out the MAPP

torch which made the connector hot enough to sweat in the solder.

Installed the battery terminal compression connector on the other end.

Finished up with the black heat shrink insulation segments applied

using a hair dryer. Installed the cables, tested and cleaned up. Came

inside to update the BillyBob wiring diagram.

Used

some of the cable to reroute to a secondary cut-off switch, then

proceeded to make a new ground cable. Removed the old #6 ground cable

and used it to measure the length for the new #2 cable. Stripped an

inch of insulation off one end and crimped the FLAPS copper ring

connector on it. Then tried to solder the connection with my small

computer tool kit soldering iron. About the time I realized it was too

small for the job, the soldering iron cord got caught on something and

kept the soldering iron from going any further in the direction my hand

was going, and my fingers went down to the the hot end of the iron

causing some of my smoke to escape my body. ~!@#$%

Good news is that the the iron wasn't very hot from it's efforts to

heat up the cable and connector and that a callosed part of my hand

only made brief contact. A couple of my fingerprints look like the

sepia woodgrain in a kid's woodburning kit but that's about it. I don't

even think I'm gonna get a blister. Enuf of this. Pulled out the MAPP

torch which made the connector hot enough to sweat in the solder.

Installed the battery terminal compression connector on the other end.

Finished up with the black heat shrink insulation segments applied

using a hair dryer. Installed the cables, tested and cleaned up. Came

inside to update the BillyBob wiring diagram.

July 12th 2003 Wuz in Pennsylvania over Independence Day for a family reunion. On the drive up, I intersected with the "Great Race" group coming out of Chattanooga in the driving rain. Those folks are real troopers, 'specially the ones driving the old open cockpit racecars from the twenties and thirties. I passed seven of the 117 contestants, drenched and bookin' right along at about sixty mph (They only use the interstates to get in and out of the host cities each day).

Before I went North, I cleaned BillyBob's taillights and managed to make them stop working in the process. Gonna try to straighten out that problem today. hooked up a pair of alligator clip jumpers between the taillight mounting studs and the rear bumper . . . Eureka! I have lights. Looks like I screwed up my ground by waxing the taillight brackets. Disassembled the taillights and brackets and sanded the mounting hole areas to improve the ground contact. Re-assembled and everything is hunky-dory again.

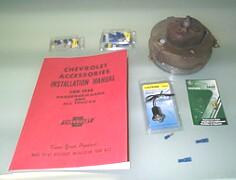

July 25th 2003 Back in early June when I got my first order from Bowtie Bits, they sent along a catalog which has a lot more stuff than the website. One of the "new" items they were listing was a 1954-59 Chevy/GMC Turn Signal Kit (#TF-549-TSKRB). This is a rebuilt original factory accessory and they are as rare as hens' teeth. I called up and Jeff McCoy answered the phone. Ordered one from him and he asked if my info was on record and I said yes. Nothing happened during June and I thought that maybe the order slipped thru the cracks but yesterday the UPS man turned up with the turn signal kit.

Now,

I can feel the spirit of my Dad again, looking over my shoulder and

giving me the dickens for buying this doo-hickey when the aftermarket

strap-on turn-signal director is working perfectly well and has the

additional functionality of four-way flashers which the original

doesn't have. "But the original has a self-canceling

feature, Dad" I offer silently and weakly. The kit

also includes a flasher (two-prong), the canceling cam, and

installation instructions for a Task Force truck (which aren't

completely applicable for BillyBob).

Now,

I can feel the spirit of my Dad again, looking over my shoulder and

giving me the dickens for buying this doo-hickey when the aftermarket

strap-on turn-signal director is working perfectly well and has the

additional functionality of four-way flashers which the original

doesn't have. "But the original has a self-canceling

feature, Dad" I offer silently and weakly. The kit

also includes a flasher (two-prong), the canceling cam, and

installation instructions for a Task Force truck (which aren't

completely applicable for BillyBob).

Last

year I got the "Chevrolet Accessories Installation Manual for 1954

Passenger Cars and All Trucks" from Chevy Duty and this book shows the

installation procedure for BillyBob. By reviewing these two manuals and

BillyBob's current wiring diagram I was able to figure out most of the

necessary connections. I want to try to make this work with my existing

three-prong flasher and include a working indicator light on the dash

so, it being a slow afternoon, I made an excursion to the Discount Auto

Parts store to pick up a Calterm #08524 Universal Miniature Bulb Socket

and a pack of GE #1445 instrument panel bulbs, hoping they are the

right size for the turn signal indicator light hole on the back of the

speedo gauge cluster. It "eyeballs" to be the same as the high beam

indicator which is what I'm trying to match here. I think I already

have a supply of bullet connectors so I should be set.

Last

year I got the "Chevrolet Accessories Installation Manual for 1954

Passenger Cars and All Trucks" from Chevy Duty and this book shows the

installation procedure for BillyBob. By reviewing these two manuals and

BillyBob's current wiring diagram I was able to figure out most of the

necessary connections. I want to try to make this work with my existing

three-prong flasher and include a working indicator light on the dash

so, it being a slow afternoon, I made an excursion to the Discount Auto

Parts store to pick up a Calterm #08524 Universal Miniature Bulb Socket

and a pack of GE #1445 instrument panel bulbs, hoping they are the

right size for the turn signal indicator light hole on the back of the

speedo gauge cluster. It "eyeballs" to be the same as the high beam

indicator which is what I'm trying to match here. I think I already

have a supply of bullet connectors so I should be set.

July 26th 2003 Stopped off at the warehouse on the way to the Krash Lab this morning to pick up BillyBob's old speedo cluster. Prelim fit experiments of the new bulb socket up under the dashboard yesterday resulted in some spirited cussing and little else. The socket is a little too big but I may be able to mitigate the problem with some creative pliers work. The old cluster will allow me to get the fit right at the workbench before crawling up under the dashboard again. The aftermarket director has seven wires and the original only has six. The one that is missing is the wire to the "P" terminal on the three-prong flasher. Since the aftermarket director has the turn indicator lights built-in and the original does not, I made the leap of logic that the "P" wire went to the indicator lamp. I pulled the "P" wire off the flasher and tested my theory . . . everything still worked but the indicator lamps. Good! I will run the "P" wire from the flasher to the indicator in the speedo cluster in the new setup. Maybe "P" stands for "Panel Light". Success! Got the new socket in and working. I mistakenly had the high beam indicator lamp in this hole before. It was relocated to the proper hole at the top of the speedo cluster.

Cut

off the blade connectors on the "new" original director wires and

crimped on bullet connectors to match my existing setup. Dug up my

steering wheel puller and took the steering wheel and old aftermarket

director off. The sky started to rumble a bit in the distance at this

point. Removed the old hub off the back of the steering wheel and

replaced it with the canceling cam. Removed the wiring clamp (where the

horn wire enters) at the bottom of the steering column.

Cut

off the blade connectors on the "new" original director wires and

crimped on bullet connectors to match my existing setup. Dug up my

steering wheel puller and took the steering wheel and old aftermarket

director off. The sky started to rumble a bit in the distance at this

point. Removed the old hub off the back of the steering wheel and

replaced it with the canceling cam. Removed the wiring clamp (where the

horn wire enters) at the bottom of the steering column.

Spent

about a half hour snaking the six wires down inside the steering

column. It's a bit tight with the steering shaft to get all those

connectors thru and care had to be taken not to break the horn wire

connection. It would be real hell to fix that! Slipped the "new"

director on the steering wheel column with the clamping screw loose.

Reinstalled the steering wheel and adjusted the director so that there

was a 1/8" gap between it and the steering wheel, then tightened the

clamp screw. Replaced the wiring clamp at the bottom of the column.

Replaced the steering wheel, connected the wires and tested.

Spent

about a half hour snaking the six wires down inside the steering

column. It's a bit tight with the steering shaft to get all those

connectors thru and care had to be taken not to break the horn wire

connection. It would be real hell to fix that! Slipped the "new"

director on the steering wheel column with the clamping screw loose.

Reinstalled the steering wheel and adjusted the director so that there

was a 1/8" gap between it and the steering wheel, then tightened the

clamp screw. Replaced the wiring clamp at the bottom of the column.

Replaced the steering wheel, connected the wires and tested.

OOPS!

Turning the steering wheel ninety degrees or more to the left beeps the

horn. Pulled the wheel, checked clearances and reinstalled a couple of

times but couldn't find the problem. The third time I put it back

together the horn problem went away. There is more of a gap now between

the steering wheel and director - about 3/16" instead of the spec 1/8".

I'm wondering if I disturbed the horn wire inside the steering mast and

grounded it. I hope not. We'll play it by ear for now (sorry 'bout

that). Gotta paint the director to match the column and wheel but we'll

save that for another time. Went inside for awhile to post updates to

BillyBob's wiring diagram. Then I went for a test run around the block

. . . works good (at least for right hand turns - won't know about left

hand turns til later when I go home).

OOPS!

Turning the steering wheel ninety degrees or more to the left beeps the

horn. Pulled the wheel, checked clearances and reinstalled a couple of

times but couldn't find the problem. The third time I put it back

together the horn problem went away. There is more of a gap now between

the steering wheel and director - about 3/16" instead of the spec 1/8".

I'm wondering if I disturbed the horn wire inside the steering mast and

grounded it. I hope not. We'll play it by ear for now (sorry 'bout

that). Gotta paint the director to match the column and wheel but we'll

save that for another time. Went inside for awhile to post updates to

BillyBob's wiring diagram. Then I went for a test run around the block

. . . works good (at least for right hand turns - won't know about left

hand turns til later when I go home).

That's about enuf fun for this episode. Too late in the day to start anything big so I'll post this log entry before going home. Got lottsa other stuff to report on down the road in other upcoming log entries. Today, when I go home to the Krash Pad, I'll be able to reward myself with a fast food burger and a cigar. On bad days, I have a "consolation" burger and cigar.

| < Back

to Intro |

You can email me at ![]() webmaster@laroke.com

webmaster@laroke.com

Issued Saturday July 26, 2003

Updated Thursday February 15, 2018

copyright © 1996-2018 Larry Robert Kephart all rights reserved

| | LRK Home | | Bio Info | | Krash Khronicles | | LAROKE | |

| | BettyLou | | BillyBob's Garage | | Rat Patrol | | Deerslayer | | Elvira | |

| | Land of the Free and Home of the Brave | |

| | Keppylou's Art | | WWI Soldier's Diary | |