| | LRK Home | | Bio Info | | Krash Khronicles | | LAROKE | |

| | BettyLou | | BillyBob's Garage | | Rat Patrol | | Deerslayer | | Elvira | |

| | Land of the Free and Home of the Brave | |

| | Keppylou's Art | | WWI Soldier's Diary | |

Tinkering with Deerslayer

![]()

DEERSLAYER LINKS including vendor sites for parts and tools as well as sites for old truck and hot rod organizations

![]()

TINKERING WITH DEERSLAYER chronicles the day-by-day maintenance and improvements episodes for Deerslayer, a '37 Chevy farm truck hot rod.

CRUISIN' WITH DEERSLAYER Roadtrips, cruise-in's and truck show stories and tall tales.

TONY'S DUNGEON Tony Pascarella's forum entries at OldGMCtrucks.com regarding Deerslayer, particularly the 302 GMC engine build in his farmhouse basement.

![]()

DEERSLAYER MAINTENANCE Ever changing detailing, oil change, lube, etc. maintenance routines specifically developed for Deerslayer, including required tools, materials and procedures.

PROJECT NAILHEAD Chronicles the rebuild of a 1954 Buick Roadmaster 322 nailhead engine as a future replacement for Deerslayer's Jimmy 302.

43. Down to Bare Bones

January

16th 2020

Slogging away at the rusted bed bolts. Was under the weather the last

few days. Still spent time out in the shop every day but didn't get as

much done. Scramblin' out from under the truck several times with the

Aztec quickstep put a kink in my operations.

January

16th 2020

Slogging away at the rusted bed bolts. Was under the weather the last

few days. Still spent time out in the shop every day but didn't get as

much done. Scramblin' out from under the truck several times with the

Aztec quickstep put a kink in my operations.

Finally got the bed off but it wasn't pretty. Last two carriage bolts turned in their anchorages. Prepared to grind the heads off when I realized they were both in ends of floating crossmembers and I could lift and lay the bedside down on its side, swing the crossmembers under the remaining board and lift the whole thing off as an assembly. Done! Beer of the day is Clipper City Brewing Company's Heavy Seas Winter Storm Imperial ESB.

January

17th 2020

Cleaned up the aftermath of the battle of the carriage bolts. Drip

tray, siphon and paint arrived for the windshield job. The drip tray

has a corrugated bottom. That's a bonus. I won't have to fashion

stand-offs for the submerged parts. Still waiting on

Evapo-Rust. In the mean time I'll be removing parts of

the drive train and some other, between the frame rails, items. I was

wrong about the running board supports being bolted. They are riveted.

I must've been having a senior moment. They are sharp on the ends and

I've been collecting bubble wrap to encase them. A person could get a

bad gash and I'm just the man for the job.

January

17th 2020

Cleaned up the aftermath of the battle of the carriage bolts. Drip

tray, siphon and paint arrived for the windshield job. The drip tray

has a corrugated bottom. That's a bonus. I won't have to fashion

stand-offs for the submerged parts. Still waiting on

Evapo-Rust. In the mean time I'll be removing parts of

the drive train and some other, between the frame rails, items. I was

wrong about the running board supports being bolted. They are riveted.

I must've been having a senior moment. They are sharp on the ends and

I've been collecting bubble wrap to encase them. A person could get a

bad gash and I'm just the man for the job.

January

20th 2020

Evapo-Rust arrived at the Krash Kubicle Friday afternoon. It was set up

at the shop and siphoned into the drip pan. Two hours after being

submerged, all the rust was gone. It took longer to set up and clean up

than than actually clean the metal.

January

20th 2020

Evapo-Rust arrived at the Krash Kubicle Friday afternoon. It was set up

at the shop and siphoned into the drip pan. Two hours after being

submerged, all the rust was gone. It took longer to set up and clean up

than than actually clean the metal.

I've said

before that there is almost something religious about bare clean metal.

Now, I've got to bone up on setting the windshield in the frame with

glass setting tape. Years ago, I did a similar op with one of

BillyBob's vent windows. I'm hoping the process isn't much different.

I've said

before that there is almost something religious about bare clean metal.

Now, I've got to bone up on setting the windshield in the frame with

glass setting tape. Years ago, I did a similar op with one of

BillyBob's vent windows. I'm hoping the process isn't much different.

January

21st 2020

Got the remainder of the exhaust system off the truck. This thing has

been in my way a long time. With the bed off, I could finally see the

hanger bolt that was giving me trouble. The entire exhaust system was

rusted together and I cut it in

half at one

point to get the header end off. It was a clean cut and I will be able

to

splice things together again without much trouble. I'm happy because

the combination of the lumpy cam with the Flowmaster muffler makes a

wicked sound that many mistake for a V8.

January

21st 2020

Got the remainder of the exhaust system off the truck. This thing has

been in my way a long time. With the bed off, I could finally see the

hanger bolt that was giving me trouble. The entire exhaust system was

rusted together and I cut it in

half at one

point to get the header end off. It was a clean cut and I will be able

to

splice things together again without much trouble. I'm happy because

the combination of the lumpy cam with the Flowmaster muffler makes a

wicked sound that many mistake for a V8.

Took the drive shaft out next. Soon as it was unbolted, the universal joint got a strip of duct tape around it, keeping the bearing cups in place and preventing the roller bearings from making their escape.

Deerslayer's tranny is scheduled to come out next. Soon

discovered I don't have a wrench that will fit between the battery box

and the drain plug so, I stopped long enuf to take out the battery box.

Beer of the day was Southern Barrel Brewing Company's Helles Lager.

January

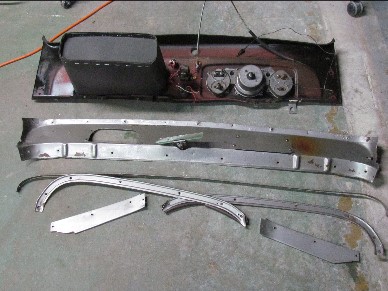

22nd 2020 Was tired of rolling around under

the truck and doin' laundry afterwards so I switched to cab disassembly

for a change of pace. The wiper motor and, hinge enclosure above the

windshield has to come off to get at the old windshield hinges.

Headliner trim, a-pillar trim and door header trim pieces have to be

removed for that to happen. Had the items, along with wiper and wiper

motor off by the time I turned the lights out in the shop for the

night.

January

22nd 2020 Was tired of rolling around under

the truck and doin' laundry afterwards so I switched to cab disassembly

for a change of pace. The wiper motor and, hinge enclosure above the

windshield has to come off to get at the old windshield hinges.

Headliner trim, a-pillar trim and door header trim pieces have to be

removed for that to happen. Had the items, along with wiper and wiper

motor off by the time I turned the lights out in the shop for the

night.

January

23rd 2020

Turned my attention to the dashboard. Looks fairly straightforward. It

should come out after four screws and the windshield crank mechanism

handle are removed. It did, tho' there was some jockeying around,

joggling this way and that, after it was loose. The next thing to

consider is the wiring still attaching it to the cab.

January

23rd 2020

Turned my attention to the dashboard. Looks fairly straightforward. It

should come out after four screws and the windshield crank mechanism

handle are removed. It did, tho' there was some jockeying around,

joggling this way and that, after it was loose. The next thing to

consider is the wiring still attaching it to the cab.

January

24th 2020 The dashboard wiring needed some

deep ponder mode time to determine the best approach. Let loose the

side cutters of war or try to preserve the existing wiring harness for

comparison when the new wiring harness is installed? Preservation won

out. Beer of the day is Christian Moerlein Brewing Company's Northern

Liberties IPA.

January

24th 2020 The dashboard wiring needed some

deep ponder mode time to determine the best approach. Let loose the

side cutters of war or try to preserve the existing wiring harness for

comparison when the new wiring harness is installed? Preservation won

out. Beer of the day is Christian Moerlein Brewing Company's Northern

Liberties IPA.

January

27th 2020

A delivery of electrical tape arrived. The windshield project can now

proceed. Cleaned the glass and placed the windshield in my neoprene

padded bench vice. Peeled the protective strip off the glass setting

tape and affixed it to the top edge and sides of the new windshield

glass with the electrical tape.

Notched the corners.

January

27th 2020

A delivery of electrical tape arrived. The windshield project can now

proceed. Cleaned the glass and placed the windshield in my neoprene

padded bench vice. Peeled the protective strip off the glass setting

tape and affixed it to the top edge and sides of the new windshield

glass with the electrical tape.

Notched the corners.

January

28th 2020 Deerslayer's cardboard headliner is

wrinkled in a few places but otherwise in good shape. I'm leaving it in

place. The five fasteners anchoring it along its centerline,

however, stand out too much for my liking. They are screws and fender

washers and my fall back plan was to paint them to blend in but I

finally happened upon the magic intarweb search term to lead me to my

preferred solution - "Upholstery Buttons". They arrived and were

installed in a matter of minutes. Beer of the day was Spencer Brewery's

Trappist Ale.

January

28th 2020 Deerslayer's cardboard headliner is

wrinkled in a few places but otherwise in good shape. I'm leaving it in

place. The five fasteners anchoring it along its centerline,

however, stand out too much for my liking. They are screws and fender

washers and my fall back plan was to paint them to blend in but I

finally happened upon the magic intarweb search term to lead me to my

preferred solution - "Upholstery Buttons". They arrived and were

installed in a matter of minutes. Beer of the day was Spencer Brewery's

Trappist Ale.

January

29th 2020

Dawn dish washing soap was used as a lubricant on the setting tape and

the upper windshield frame was urged into position. A rubber mallet

helped to seat the glass in the channel. The assembly was turned upside

down in the vise and the process was repeated for the bottom half.

Finally, a new blade in my utility knife made short work of trimming

the excess glass setting tape and electrical tape remnants.

January

29th 2020

Dawn dish washing soap was used as a lubricant on the setting tape and

the upper windshield frame was urged into position. A rubber mallet

helped to seat the glass in the channel. The assembly was turned upside

down in the vise and the process was repeated for the bottom half.

Finally, a new blade in my utility knife made short work of trimming

the excess glass setting tape and electrical tape remnants.

I had forebodings on how the glass setting tape operation was going to go but it turned out to be easier than anticipated. The windshield was then masked for painting. The windshield frame could have been painted before assembly but I have a bad history of marring freshly painted items and I wanted to avoid that fate if I could.

After masking the glass, the frame was PRE-paint prepped and

given two coats of Eastwood's Self-Etching primer. This was followed up

by four coats of Duplicolor's Black Wheel Paint.

January

30th 2020 Got the dashboard detached from the

wiring. I did have to snip some wires when getting at the connectors

would have required an excess of cursing and contorted body angles. Was

happy to get the water temperature gauge capillary tube out intact.

Beer of the day was Christian Moerlein Brewing Company's Barbarossa

Dark Lager.

January

30th 2020 Got the dashboard detached from the

wiring. I did have to snip some wires when getting at the connectors

would have required an excess of cursing and contorted body angles. Was

happy to get the water temperature gauge capillary tube out intact.

Beer of the day was Christian Moerlein Brewing Company's Barbarossa

Dark Lager.

January

31st 2020 The weather seal was pressed into

its channel with the help of a plastic pry tool,

starting at the bottom center of the frame and working around it back

to the point of beginning. It was tedius work and I'll have a bruised

palm for a day or two.

January

31st 2020 The weather seal was pressed into

its channel with the help of a plastic pry tool,

starting at the bottom center of the frame and working around it back

to the point of beginning. It was tedius work and I'll have a bruised

palm for a day or two.

Some of the

primer got under the masking tape and that still

has to be

cleaned off the glass with lacquer thinner. Smudges and fingerprints

from the hand-to-hand combat with the weather seal also have to be

cleaned, then I can mark finished to this task. Okay, out with the old

windshield and in with the new

windshield

when the cab painting is done. Up on the shelf until then.

Some of the

primer got under the masking tape and that still

has to be

cleaned off the glass with lacquer thinner. Smudges and fingerprints

from the hand-to-hand combat with the weather seal also have to be

cleaned, then I can mark finished to this task. Okay, out with the old

windshield and in with the new

windshield

when the cab painting is done. Up on the shelf until then.

February

3rd 2020 Next small task is the rear cab window.

The trim piece is a cast item, held in place by clutch head screws from

the interior side. For those not familiar with clutch head screws, they

are a fastener anybody working on an old Chevy eventually encounters

and it is usually a whiskey tango foxtrot moment. They are similar to

Torx or Allen head fasteners but instead of a star or hex shape, clutch

head fasteners are bowtie shaped. I purchased clutch head screwdrivers

and bits long ago.

February

3rd 2020 Next small task is the rear cab window.

The trim piece is a cast item, held in place by clutch head screws from

the interior side. For those not familiar with clutch head screws, they

are a fastener anybody working on an old Chevy eventually encounters

and it is usually a whiskey tango foxtrot moment. They are similar to

Torx or Allen head fasteners but instead of a star or hex shape, clutch

head fasteners are bowtie shaped. I purchased clutch head screwdrivers

and bits long ago.

When I got all the fasteners out, the rear window surround

came off the back. The glass was still held in place by the rear window

seal. I gave the window a couple of whacks with a rubber mallet and it

didn't budge. Examined the glass and rubber and found the glass

to be clear and the seal to be intact without sign of cracking or

hardening. I decided to leave the glass and seal in place. Beer of the

day was Spencer Brewery's Premium Pilsner.

February

4th 2020 A few weeks ago when I saw that the

cab bodywork was creeping up on me, I used it as an excuse to get a

shiny new tool, the Eastwood Contour SCT Surface Conditioning Tool. I

decided to get my feet wet with this gadget by using it to take the

paint off the rear window surround. It did a good job. Took about

fifteen minutes at the lowest speed setting. I think this might be the

beginning of a beautiful friendship.

February

4th 2020 A few weeks ago when I saw that the

cab bodywork was creeping up on me, I used it as an excuse to get a

shiny new tool, the Eastwood Contour SCT Surface Conditioning Tool. I

decided to get my feet wet with this gadget by using it to take the

paint off the rear window surround. It did a good job. Took about

fifteen minutes at the lowest speed setting. I think this might be the

beginning of a beautiful friendship.

February

5th 2020 Got some more items off the truck. A frame

cross

member that Tony fabricated that does not support the transmission but

has to be removed to get it out. My friend Gato put the cross member in

last time when we replaced the clutch. He also lifted the T5 five speed

above his head, by himself,

to install it at that time so you can imagine how tight those bolts

were.

February

5th 2020 Got some more items off the truck. A frame

cross

member that Tony fabricated that does not support the transmission but

has to be removed to get it out. My friend Gato put the cross member in

last time when we replaced the clutch. He also lifted the T5 five speed

above his head, by himself,

to install it at that time so you can imagine how tight those bolts

were.

The mechanical speedo cable, tach, turn signal director and fire extinguisher and support were also removed.

I managed to keep the wiring harness about 75% intact taking

it out. I gained new admiration for Tony's wiring Kung Fu as I cussed

my way thru the task. Beer of the day was DuClaw Brewing Co's

Everything is Taken Hoppy Lager.

February

6th 2020 Finished with the rear window

surround. As with the windshield frame, it was PRE paint prepped and

given two coats of Eastwood's self-etching primer followed by four

coats of Duplicolor black wheel paint. It can now join the windshield

on the shelf until the cab is painted.

February

6th 2020 Finished with the rear window

surround. As with the windshield frame, it was PRE paint prepped and

given two coats of Eastwood's self-etching primer followed by four

coats of Duplicolor black wheel paint. It can now join the windshield

on the shelf until the cab is painted.

February

7th 2020 Continued stripping down the cab interior,

removing insulation and various doodads. About the only thing left is

the crotch cooler cowl vent. Need to study that a bit. The headliner

and remaining

interior trim will stay but everything else comes out for painting ops.

Beer of the day was Adirondack Brewery's Iroquois Pale Ale.

February

7th 2020 Continued stripping down the cab interior,

removing insulation and various doodads. About the only thing left is

the crotch cooler cowl vent. Need to study that a bit. The headliner

and remaining

interior trim will stay but everything else comes out for painting ops.

Beer of the day was Adirondack Brewery's Iroquois Pale Ale.

February

10th 2020 Freed up my tranny jack from the gas

tank sitting on it and got the Borg-Warner T5 Transmission out. I try

to schedule the heavy lifting for the weekends 'cause, after twelve

hours in the Krash Kubicle on the weekdays, I usually don't have the

gumption to roll around on the floor and get greasy.

February

10th 2020 Freed up my tranny jack from the gas

tank sitting on it and got the Borg-Warner T5 Transmission out. I try

to schedule the heavy lifting for the weekends 'cause, after twelve

hours in the Krash Kubicle on the weekdays, I usually don't have the

gumption to roll around on the floor and get greasy.

The Jimmy 302 engine block and bellhousing will be the last

major Item to exit the chassis. We are now basically down to bare

bones. Most items now coming off the truck will be cleaned up and put

right back on. We're movin' into a scraping and painting phase. Beer of

the day was Fulton Brewery's Lonely Blonde American Blonde Ale.

| < Back

to Intro |

You can email me at ![]() webmaster@laroke.com

webmaster@laroke.com

Issued Monday February 10, 2020

copyright © 2008-2020 Larry R. Kephart all rights reserved

| | LRK Home | | Bio Info | | Krash Khronicles | | LAROKE | |

| | BettyLou | | BillyBob's Garage | | Rat Patrol | | Deerslayer | | Elvira | |

| | Land of the Free and Home of the Brave | |

| | Keppylou's Art | | WWI Soldier's Diary | |