| | LRK Home | | Bio Info | | Krash Khronicles | | LAROKE | |

| | BettyLou | | BillyBob's Garage | | Rat Patrol | | Deerslayer | | Elvira | |

| | Land of the Free and Home of the Brave | |

| | Keppylou's Art | | WWI Soldier's Diary | |

Tinkering with Deerslayer

![]()

DEERSLAYER LINKS including vendor sites for parts and tools as well as sites for old truck and hot rod organizations

![]()

TINKERING WITH DEERSLAYER chronicles the day-by-day maintenance and improvements episodes for Deerslayer, a '37 Chevy farm truck hot rod.

CRUISIN' WITH DEERSLAYER Roadtrips, cruise-in's and truck show stories and tall tales.

TONY'S DUNGEON Tony Pascarella's forum entries at OldGMCtrucks.com regarding Deerslayer, particularly the 302 GMC engine build in his farmhouse basement.

![]()

DEERSLAYER MAINTENANCE Ever changing detailing, oil change, lube, etc. maintenance routines specifically developed for Deerslayer, including required tools, materials and procedures.

PROJECT NAILHEAD Chronicles the rebuild of a 1954 Buick Roadmaster 322 nailhead engine as a future replacement for Deerslayer's Jimmy 302.

42. On a roll

December

13th 2019

Next task is to clean and paint Deerslayer's front wheels. There is

method to my madness. The wheels will be put back on the truck soon to

reposition it with the Go-Jack wheel dollies and I want to give the

paint around the lugs some time to cure and harden.

December

13th 2019

Next task is to clean and paint Deerslayer's front wheels. There is

method to my madness. The wheels will be put back on the truck soon to

reposition it with the Go-Jack wheel dollies and I want to give the

paint around the lugs some time to cure and harden.

Cleaned and organized the tools and parts left over in the

aftermath of the disk brake and head work ops, then set to work washing

the backside of the first wheel with a Dawn dish washing soap and water

solution, the only thing I had on hand. Beer of the day was Sumerian

Brewing Company's Holy Water Citra IPA.

December

17th 2019

Made a pass with wire cup and wheel in air-powered angle grinder

followed by several cycles of cleaning with Oil Eater degreaser. I was

surprised to find it as effective on this dry brake grime as it is on

greasy surfaces.

December

17th 2019

Made a pass with wire cup and wheel in air-powered angle grinder

followed by several cycles of cleaning with Oil Eater degreaser. I was

surprised to find it as effective on this dry brake grime as it is on

greasy surfaces.

After the Oil Eater cleaning, the rusty areas were

treated with a course grit foam sanding block and the whole

surface to be painted was gone over with a Scotchbrite pad.

Went and hunted up my Wheel Masks, a tool I'd gotten from

Eastwood in the last century. These simple sheet metal bands are the

best thing since sliced bread as far as wheel painting is concerned. I

need all the help I can get. My tape masking Kung Fu is not strong. PRE

Paint Prepped the wheel and gave required areas two coats of

Eastwood's

Self-etching Primer, followed up by four coats of Dupli-Color Black

High Performance Wheel Paint over the entire wheel side.

December

18th 2019

After the first side of the first wheel was painted, I adjusted my

procedure. The wire cup and wheel step was eliminated. I couldn't get

to the nooks and crannies and as much paint was being removed as dirt,

necessitating more primer. If I had known beforehand how well the Oil

Eater was going to do, the air-powered angle grinder would have never

come out of the drawer for this operation. Deerslayer's front wheels

are done for now and can be put off to the side for the paint to

harden. Beer of the day is RJ

Rockers Brewing Company's Son of a Peach Wheat Ale. As a rule, wheat

ales do not agree with me but this one tastes, well . . . just peachy.

December

18th 2019

After the first side of the first wheel was painted, I adjusted my

procedure. The wire cup and wheel step was eliminated. I couldn't get

to the nooks and crannies and as much paint was being removed as dirt,

necessitating more primer. If I had known beforehand how well the Oil

Eater was going to do, the air-powered angle grinder would have never

come out of the drawer for this operation. Deerslayer's front wheels

are done for now and can be put off to the side for the paint to

harden. Beer of the day is RJ

Rockers Brewing Company's Son of a Peach Wheat Ale. As a rule, wheat

ales do not agree with me but this one tastes, well . . . just peachy.

December

19th 2019

Organized, put away the wheel painting materials and cleared the

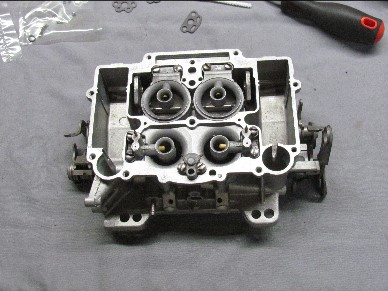

deck for the next planned task. Deerslayer's 400 CFM Carter AFB

Carburetor has been in pieces for 3-1/2 years. Long past time to get it

back together.

December

19th 2019

Organized, put away the wheel painting materials and cleared the

deck for the next planned task. Deerslayer's 400 CFM Carter AFB

Carburetor has been in pieces for 3-1/2 years. Long past time to get it

back together.

When I took this thing apart, the parts were organized in

muffin tins with post-it note labels. Hopefully, this will cut down my

confusion during reassembly. Most of the ferrous parts have developed

surface rust over the years. They will have to spend some time in the

Evapo-Rust basket.

December

20th 2019

It's time to strip down and remove Deerslayer's cab for the next phase

of the work while I'm scratching my head over the carburetor.

Dropped the front end down on the jack stands to level out the truck.

Now

I can jockey the door lift into position to take off the doors. Some of

the door hinge screws want to stay where they are. Now, I'm trying

different methods of extraction, with limited success. Beer of the day

is River Horse Brewing Company's Oatmeal Milk Stout.

December

20th 2019

It's time to strip down and remove Deerslayer's cab for the next phase

of the work while I'm scratching my head over the carburetor.

Dropped the front end down on the jack stands to level out the truck.

Now

I can jockey the door lift into position to take off the doors. Some of

the door hinge screws want to stay where they are. Now, I'm trying

different methods of extraction, with limited success. Beer of the day

is River Horse Brewing Company's Oatmeal Milk Stout.

December

23rd 2019

All the hinge leaf screws were small but stubborn. I was successful at

getting the driver side upper hinge cab side screws out with manual

impact driver but none of the others would bust loose. I also tried MAP

gas, Kroil penetrating oil and air-powered impact wrench, all to no

avail. I got the driver side lower hinge leaf door side screws loose

but they had hex nuts inside the door and I had to take off the inner

door panel to get at those. I finally got the door off with the upper

hinge still on the door and the lower hinge still on the cab.

December

23rd 2019

All the hinge leaf screws were small but stubborn. I was successful at

getting the driver side upper hinge cab side screws out with manual

impact driver but none of the others would bust loose. I also tried MAP

gas, Kroil penetrating oil and air-powered impact wrench, all to no

avail. I got the driver side lower hinge leaf door side screws loose

but they had hex nuts inside the door and I had to take off the inner

door panel to get at those. I finally got the door off with the upper

hinge still on the door and the lower hinge still on the cab.

Went to the passenger side door and found more of the same despair. Then, palm slap to the forehead! I'm overthinking things again. I was doing things here the way I did when I took BillyBob's doors off but Billybob has concealed hinges. Deerslayer's doors have exterior hinges. All I have to do is drive the hinge pins out with a punch! I did and the passenger side door was off in five minutes instead of the hours long ordeal of the driver side door.

Damnation! Some days the bear gets you and some days, you iz the bear. Beer of the day was Southern Barrel Brewing Company's Damn Yankee IPA.

December

24th 2019

While I was pondering the problems of clutch and brake pedal, and other

obstructions blocking cab removal, I went to work on items that were

relatively easy. The rear fenders gave me some trouble in the form of a

few rusted bolts I had to grind off. Otherwise, the fenders and running

boards came away easier than I expected. The running board supports are

bolted in place, not riveted like BillyBob, so those "shin killers"

will be removed too.

December

24th 2019

While I was pondering the problems of clutch and brake pedal, and other

obstructions blocking cab removal, I went to work on items that were

relatively easy. The rear fenders gave me some trouble in the form of a

few rusted bolts I had to grind off. Otherwise, the fenders and running

boards came away easier than I expected. The running board supports are

bolted in place, not riveted like BillyBob, so those "shin killers"

will be removed too.

December

26th 2019

Started striping the glued on insulation and other easy items from the

cab interior. That's when I discovered or, rather re-discovered (since

I had applied the insulation years ago), that the firewall kick plate,

including the area of the clutch and brake pedals, was a bolt in item.

The area surrounding the pedal shafts splits into two pieces. The

pedals

would not restrict the cab lift operation after all. Beer of the day is

RJ Rockers Brewing Company's Bell Ringer Double Pale Ale. I've been

punched by this brew before.

December

26th 2019

Started striping the glued on insulation and other easy items from the

cab interior. That's when I discovered or, rather re-discovered (since

I had applied the insulation years ago), that the firewall kick plate,

including the area of the clutch and brake pedals, was a bolt in item.

The area surrounding the pedal shafts splits into two pieces. The

pedals

would not restrict the cab lift operation after all. Beer of the day is

RJ Rockers Brewing Company's Bell Ringer Double Pale Ale. I've been

punched by this brew before.

December

27th 2019

I unscrewed the firewall kick plate sheet metal and went into Deep

Ponder Mode. This was a game changer. The reasons for lifting the cab

have largely vanished and the diminishing returns threshold crossed. I

have all the access I need from above except directly

under the seat base and that is a "quiet" area. Not much has to be

done on my back there except clean and paint the frame rails and cab

floor. Yogi Berra said "When you

come to a fork in the road, take it." I moved on to the task of

preparing the bed for removal.

December

27th 2019

I unscrewed the firewall kick plate sheet metal and went into Deep

Ponder Mode. This was a game changer. The reasons for lifting the cab

have largely vanished and the diminishing returns threshold crossed. I

have all the access I need from above except directly

under the seat base and that is a "quiet" area. Not much has to be

done on my back there except clean and paint the frame rails and cab

floor. Yogi Berra said "When you

come to a fork in the road, take it." I moved on to the task of

preparing the bed for removal.

December

30th 2019

Back to the Carter AFB. This thing has been apart so long, a

recap is in order. Originally I tore it down for a standard rebuild. I

got an ultrasonic cleaner to brighten it up. The first cleaner was

faulty and it had to be replaced. The second cleaner worked but I ended

up with main castings of different shades of gray. I was unhappy. My

friend, Johan Amy, suggested vapor blasting. I read up on it and

agreed. I tore down the AFB to the basic castings and that's where

things went South. I twisted off screws and buggered my repair

attempts. John Carey's machining skills and Johan Amy's vapor blasting

saved my bacon. Ironically, Johan told me I did not have to break the

AFB

down that far for the process. And that's where we are right now.

December

30th 2019

Back to the Carter AFB. This thing has been apart so long, a

recap is in order. Originally I tore it down for a standard rebuild. I

got an ultrasonic cleaner to brighten it up. The first cleaner was

faulty and it had to be replaced. The second cleaner worked but I ended

up with main castings of different shades of gray. I was unhappy. My

friend, Johan Amy, suggested vapor blasting. I read up on it and

agreed. I tore down the AFB to the basic castings and that's where

things went South. I twisted off screws and buggered my repair

attempts. John Carey's machining skills and Johan Amy's vapor blasting

saved my bacon. Ironically, Johan told me I did not have to break the

AFB

down that far for the process. And that's where we are right now.

De-rusted primary and secondary throttle shafts and installed them, using my spare carb as a guide. New screws were used with threadlocker blue on the throttle plates in lieu of staking them. I could foresee getting myself into real trouble doing that as I've never done it before. I've already screwed up the throttle shafts enuf.

Choke plate and shafts were next. Bit of a setback here. Noticed one of the very small screws was shorter. Pulled the shaft out of the Evapo-Rust and found the other end of the screw still in it. I must have noticed this at the time I broke it but forgot the traumatic experience.

Okay, cannibalize the spare carb's choke shaft and clean it

with Oil Eater. Done, assemble . . . Whiskey, Tango, Foxtrot! Shafts

are ever so slightly different and screw holes are off. Salvage the

choke plate from the spare carb as well and clean it. Attempt assembly

a second time and it goes together this time. On to the next challenge.

December

31st 2019

Put the wheels back on and lowered the Deerslayer. Dragged the Go-Jaks

over and positioned them. Pushed and dragged the truck around until it

was perpendicular to its previous position with the engine bay

poking into the operating theater under the loft. Disengaged the

Go-Jaks and stored them under BillyBob. Started clearing out

Deerslayer's bed. Thirsty work and it wore me out. Beer of the day is

Red River Brewing Company's Penalty Bock Lager.

December

31st 2019

Put the wheels back on and lowered the Deerslayer. Dragged the Go-Jaks

over and positioned them. Pushed and dragged the truck around until it

was perpendicular to its previous position with the engine bay

poking into the operating theater under the loft. Disengaged the

Go-Jaks and stored them under BillyBob. Started clearing out

Deerslayer's bed. Thirsty work and it wore me out. Beer of the day is

Red River Brewing Company's Penalty Bock Lager.

January

2nd 2020

Emptied Deerslayer's bed slowly as I organized the parts so I wouldn't

loose track of them. Removed the tailgate and puzzled over the

logistics of moving the heaviest items, the two Latham superchargers.

The Positraction rear end chunk was lighter but still heavy from this

geezer's perspective.

January

2nd 2020

Emptied Deerslayer's bed slowly as I organized the parts so I wouldn't

loose track of them. Removed the tailgate and puzzled over the

logistics of moving the heaviest items, the two Latham superchargers.

The Positraction rear end chunk was lighter but still heavy from this

geezer's perspective.

I was hoping I could dismantle the bed from the top down. I knew it was wishful thinking. Like all old pickup beds, the bed boards are held in place by bed strips attached by a grid of carriage bolts and fender washers. The hex nuts are all accessed from the underside.

First thing I discovered was that a few of the carriage bolts were above the gas tank. It would have to come out. It's still full of corn squezzin's stuff that used to be ethanol gas. It's heavy. Positioned my transmission jack under it for support and took off the tank strap hex nuts inboard, next to the axle, because, as Murphy would have it, they weren't halfway up the threaded rod as the more accessible outboard strap anchors were. Dirty work. Cut the fuel line with shears and rolled the tank out.

Deerslayer's builder, Tony, had connected the sender with

blade terminals so I didn't have to cut the wires. He also

fashioned a vent line that resided in the rear, right-side, stake

pocket.

Pretty neat.

January

3rd 2020

The Carter AFB is a touch different from the ones being rebuilt in the

videos I've been studying and I've been coping with that best I can.

When it came time to reinstall the jets, the primaries were located as

in the video but the secondaries were not at the bottom of the fuel

bowls where they are in the video and I removed them so long ago I

couldn't remember where they came from. Eventually located them at the

bottom of deep wells under the secondary venturi mounts.

January

3rd 2020

The Carter AFB is a touch different from the ones being rebuilt in the

videos I've been studying and I've been coping with that best I can.

When it came time to reinstall the jets, the primaries were located as

in the video but the secondaries were not at the bottom of the fuel

bowls where they are in the video and I removed them so long ago I

couldn't remember where they came from. Eventually located them at the

bottom of deep wells under the secondary venturi mounts.

I had to go into Deep Ponder Mode to figure a way to re-install them there. Hit upon an idea to use a thin pipe cleaner by putting the jet on the end of the pipe cleaner and using the pipe cleaner to get the jet started in the threads where a long screwdriver could finish the job. It worked well.

Accelerator pump jet housing, check weight, primary and secondary venturis and their assorted gaskets were next. These items were gritty and dirty and I couldn't remember why at first. Slowly dawned on me that I had not figured out the best way to clean these small parts and keep them organized at the same time when my activity ground to a halt. I did, however, get a fresh gallon of Chem-Dip before that happened and it beckoned now.

Started cleaning parts with a thirty minute bath as I needed them. Got the pump jet housing and venturis in place. Many parts will interchange and you can get things wrong and I did, occasionally, so my efforts had to be repeated a couple of times.

January

6th 2020

Started taking the bed strip carriage bolts out. The first half-dozen

went easy then, having been lulled into a good mood, Murphy hit me

with two in a row that just turned in their

anchorages. I

had to get out the electric angle grinder and grind the carriage bolt

heads off those. Progress continued to be be spotty.

January

6th 2020

Started taking the bed strip carriage bolts out. The first half-dozen

went easy then, having been lulled into a good mood, Murphy hit me

with two in a row that just turned in their

anchorages. I

had to get out the electric angle grinder and grind the carriage bolt

heads off those. Progress continued to be be spotty.

Eventually found all the fasteners holding the passenger bed

side on and got it off. Beer of the day was Clipper City Brewing

Company's Heavy Seas

Loose Cannon Hops IPA.

January

7th 2020

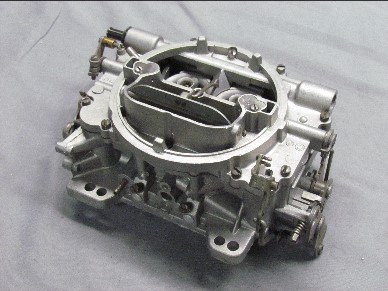

I couldn't find the new accelerator pump in pile of rebuilding parts so

I took time out to completely clean up the other workbench where I tore

the

Carter AFB apart. Found the new pump, along with an unopened "Carter

Strip Kit"

from the sixties containing a variety of jets and metering rods for the

drag strip. I don't have the knowledge to make use of the strip kit so

it stays sealed.

January

7th 2020

I couldn't find the new accelerator pump in pile of rebuilding parts so

I took time out to completely clean up the other workbench where I tore

the

Carter AFB apart. Found the new pump, along with an unopened "Carter

Strip Kit"

from the sixties containing a variety of jets and metering rods for the

drag strip. I don't have the knowledge to make use of the strip kit so

it stays sealed.

Installed the new float seats and needles, then checked the new main gaskets against the old gasket to determine the correct one. Had two sheet metal items left over in the muffin tins that are not mentioned in any of the videos. I put them in the Evapo-Rust basket and tore down the spare AFB a little further to find out what they were. Turned out to be fuel bowl baffles.

The spare AFB had better floats so I submerged those floats

under water for a day to check if they had leaks.

I then set the floats and adjusted them. Placed the new accelerator

pump

and spring and it was time to screw the top casting back unto the

bottom.

January

8th 2020

Put the AFB top and bottom together. Installed the accelerator pump

linkage and choke linkage, installed the metering rods and springs,

installed the idle mix screws, idle speed screw and fuel inlet. Found

some old photos I

took before disassembly and saw I had the manual choke linkage bass

ackwards so I fixed that.

January

8th 2020

Put the AFB top and bottom together. Installed the accelerator pump

linkage and choke linkage, installed the metering rods and springs,

installed the idle mix screws, idle speed screw and fuel inlet. Found

some old photos I

took before disassembly and saw I had the manual choke linkage bass

ackwards so I fixed that.

Purty shure I got it

right now but the proof is in the pudding. We won't know until the

engine

is reassembled. Time to Seran wrap this baby and put it on the shelf

until then. Beer of the day is Sumerian Brewing Company's Lucidity

Czech Style Pilsner.

January

9th 2020 With the carb off the work bench,

it's time to blow the dust off another half finished task, Deerslayer's

new windshield. I quit working on this just short of six years ago. The

repop windshield frame was bare metal then. Got on the intarweb and

ordered a heavy duty 24 x 48 x 2 inch deep plastic drip pan and five

more gallons of Evapo-Rust to submerge the rusty window frame parts.

January

9th 2020 With the carb off the work bench,

it's time to blow the dust off another half finished task, Deerslayer's

new windshield. I quit working on this just short of six years ago. The

repop windshield frame was bare metal then. Got on the intarweb and

ordered a heavy duty 24 x 48 x 2 inch deep plastic drip pan and five

more gallons of Evapo-Rust to submerge the rusty window frame parts.

January

10th 2020 Originally, my plans called for

refinishing the bed boards that Tony had made locally from oak but

several of them are too far gone to

save. Edges are crumbling and, at eye level, the bed undulates like sea

swells. I will go with paint on pine this time. I've had it with

varnishes and stains. This section is in better shape than most of the

bed. Maybe the moisture from my bottle cap collection helped. Beer of

the day is Sudwerk Brewing Company's Rye of the Lager.

January

10th 2020 Originally, my plans called for

refinishing the bed boards that Tony had made locally from oak but

several of them are too far gone to

save. Edges are crumbling and, at eye level, the bed undulates like sea

swells. I will go with paint on pine this time. I've had it with

varnishes and stains. This section is in better shape than most of the

bed. Maybe the moisture from my bottle cap collection helped. Beer of

the day is Sudwerk Brewing Company's Rye of the Lager.

| < Back

to Intro |

You can email me at ![]() webmaster@laroke.com

webmaster@laroke.com

Issued Friday January 10, 2020

copyright © 2008-2020 Larry R. Kephart all rights reserved

| | LRK Home | | Bio Info | | Krash Khronicles | | LAROKE | |

| | BettyLou | | BillyBob's Garage | | Rat Patrol | | Deerslayer | | Elvira | |

| | Land of the Free and Home of the Brave | |

| | Keppylou's Art | | WWI Soldier's Diary | |