| | LRK Home | | Bio Info | | Krash Khronicles | | LAROKE | |

| | BettyLou | | BillyBob's Garage | | Rat Patrol | | Deerslayer | | Elvira | |

| | Land of the Free and Home of the Brave | |

| | Keppylou's Art | | WWI Soldier's Diary | |

Tinkering with Deerslayer

![]()

DEERSLAYER LINKS including vendor sites for parts and tools as well as sites for old truck and hot rod organizations

![]()

TINKERING WITH DEERSLAYER chronicles the day-by-day maintenance and improvements episodes for Deerslayer, a '37 Chevy farm truck hot rod.

CRUISIN' WITH DEERSLAYER Roadtrips, cruise-in's and truck show stories and tall tales.

TONY'S DUNGEON Tony Pascarella's forum entries at OldGMCtrucks.com regarding Deerslayer, particularly the 302 GMC engine build in his farmhouse basement.

![]()

DEERSLAYER MAINTENANCE Ever changing detailing, oil change, lube, etc. maintenance routines specifically developed for Deerslayer, including required tools, materials and procedures.

PROJECT NAILHEAD Chronicles the rebuild of a 1954 Buick Roadmaster 322 nailhead engine as a future replacement for Deerslayer's Jimmy 302.

45. Paint and Body

March

11th 2020

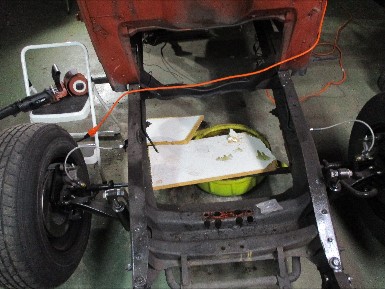

I didn't have suitable materials for "scaffolding" to reach the top of

the truck for the paint and bodywork operations. I cheated and used

some particleboard shelving I had layin' around. I was punished for

that foolishness before long. Standing on the shelf I had placed over

the frame rails in front of the firewall but, with my feet too far from

the frame rails, the particleboard broke and I went down. The engine

oil drain pan was beneath me but I landed just right and it didn't

become a carnival midway dunk tank episode. I didn't get hurt and I

think the Great Mechanic of the universe gave me a mulligan.

March

11th 2020

I didn't have suitable materials for "scaffolding" to reach the top of

the truck for the paint and bodywork operations. I cheated and used

some particleboard shelving I had layin' around. I was punished for

that foolishness before long. Standing on the shelf I had placed over

the frame rails in front of the firewall but, with my feet too far from

the frame rails, the particleboard broke and I went down. The engine

oil drain pan was beneath me but I landed just right and it didn't

become a carnival midway dunk tank episode. I didn't get hurt and I

think the Great Mechanic of the universe gave me a mulligan.

March

12th 2020

Starting the die grinder burr hunt. I will clean and inventory as I go

along in the search. Started with my Dad's machinist tool box. Moved

everything and vacuumed the same re-roofing debris that was on the

truck.

March

12th 2020

Starting the die grinder burr hunt. I will clean and inventory as I go

along in the search. Started with my Dad's machinist tool box. Moved

everything and vacuumed the same re-roofing debris that was on the

truck.

There was a coping saw, small vise and two dead multi-meters outside the box. The top compartment held computer diagnostic boards and LAN tools from the nineties, technology long gone. In the drawers were a jewelers screwdriver set, razor blade scraper, tweezers, key fobs and trinkets, novelty playin' cards, decals and dash plaques, set of micrometers, set of small hole gauges, set of small taps and dies and crimpers.

In the thrift store chest below were a blind hole bearing puller set, master torx kit, stud extractor set, impact tool kit, screw extractor kit, brake tube flaring tool, vernier calipers, hole gauges, spring scale, disk brake caliper tool set, dial indicator, piston ring installer, letter and number punch set, the dreaded ridge reamer, piston ring compressor, dial bore gauge, valve spring compressor, harmonic balancer installer and puller set and Dad's ring groove cleaner.

But no die grinder burrs or bits.

March

13th 2020

Second pass over the cab exterior, this time with Scotchbrite "cookies"

in the air-powered angle grinder to get the nooks and crannies the

Eastwood drum can't reach and eighty years of character bumps and dents

I'm going to treat with filler before painting. Also took the more

aggressive Eastwood 40 grit drum over the cowl bottoms where rust was

bubbling thru.

March

13th 2020

Second pass over the cab exterior, this time with Scotchbrite "cookies"

in the air-powered angle grinder to get the nooks and crannies the

Eastwood drum can't reach and eighty years of character bumps and dents

I'm going to treat with filler before painting. Also took the more

aggressive Eastwood 40 grit drum over the cowl bottoms where rust was

bubbling thru.

After getting all the bumps and dents I could see. I gave the

cab exterior a Dawn dish soap and water wash down to see what I missed.

Beer

of the day was Fordham & Dominion Brewing Company's Back Stage IPA.

March

16th 2020

The cab exterior painting ops are being divided into three segments for

the rest of the work. The first segment will be the top down to the

belt line, followed by the back side bottom and then the firewall area.

I dragged an old folding table out of the corner and set it up as a

paint and bodywork station for the duration of the work.

March

16th 2020

The cab exterior painting ops are being divided into three segments for

the rest of the work. The first segment will be the top down to the

belt line, followed by the back side bottom and then the firewall area.

I dragged an old folding table out of the corner and set it up as a

paint and bodywork station for the duration of the work.

March

17th 2020

Searched the next two tool boxes in the die grinder burr hunt.

March

17th 2020

Searched the next two tool boxes in the die grinder burr hunt.

Outside the boxes were a Starrett precision straight edge, a battery tender and a master disconnect set. The top compartment of the top box had a Sons & Streiffe slide rule, a few wrist watches, novelty sun glasses, several padlocks, feet & inches calculator, key fobs, Masonic jewelry, high school graduation tassel and other assorted trinkets.

Below that was a screwdriver and pick drawer, vice grip drawer, channellocks, snap ring pliers, needle nose pliers drawer, monkey wrench drawer and a allen head socket set, scissors assortment, small torx set, allen wrench set, small socket adapters, tap socket adapter set drawer.

The lower toolbox top compartment was empty except for some

dust bunnies and an ancient computer password on a post-it note. Below

were a pliers, side cutters and bent needle nose drawer, misc sockets,

extensions, combo wrenches, tubing wrenches, ratchet wrenches drawer,

and a hammers, mallets, punches, drifts and files drawer.

In the open compartment below was a seal installer set, hand laser marker, large screwdriver bits, body work slapper hammer, heavy duty drywall hooks, box of batteries and a box of hole saws.

No die grinder burrs were found yet.

March

19th 2020

Cab bodywork and shop organization continues. Next in line is the shop

"library". In plain sight is my Dad's Heathkit Oscilloscope that he and

my brother assembled. In addition were a computer tool set, jeweler's

drill, X-Acto knife set, tea filter and an alligator clip work holder.

March

19th 2020

Cab bodywork and shop organization continues. Next in line is the shop

"library". In plain sight is my Dad's Heathkit Oscilloscope that he and

my brother assembled. In addition were a computer tool set, jeweler's

drill, X-Acto knife set, tea filter and an alligator clip work holder.

Below, Swedish ammo boxes that carried spare parts on both of BillyBob's road trips a decade ago still contain mostly BillyBob spare parts, some of which can be used on the Deerslayer reconstruction.

Alternators, diodes, voltage regulators and wheel bearings are in box 1. Heater hose, hose clamps, vacuum tubing and gas line hose are in box 2. More heater hose, thermostat and ballast resistor reside in box 3. Wheel cylinders, brake shoes, drum brake parts and hoses are in box 4. 6 volt starter, battery cables and terminals are in box 5. Fuel pump, fuel filter and filter elements reside in box 6. Box 7 is filled with a BillyBob bolt collection. Distributors, both points and HEI, voltage regulators, spark plugs, coils, both points and HEI, condensers and HEI module are in box 8. box 9 contains an inner tube, speedometer cable, spring shackles, throwout bearing, wheel bearings and seals, universal joint kit and tie rod ends.

The die grinder bits and burrs have yet to be found. Beer of the day was Tommyknocker Brewery & Pub's Imperial Nut Brown Ale.

March

23rd 2020

Third pass over the cab exterior above the belt line. Scotchbrite

cookies on two more dents

I discovered and abrasive buffs in the Dremel motor tool in the cowl

vent channels, door hinges and around the rear window. Another washing

of the cab

top with Dawn dish soap and I spied two more dents previously missed,

March

23rd 2020

Third pass over the cab exterior above the belt line. Scotchbrite

cookies on two more dents

I discovered and abrasive buffs in the Dremel motor tool in the cowl

vent channels, door hinges and around the rear window. Another washing

of the cab

top with Dawn dish soap and I spied two more dents previously missed,

Finally, I was to the point where I could PRE paint prep the

dent areas and slather them with some filler. Still waiting for ordered

sandpaper for blocking. Have to make do with what I have on hand.

Truckers, God bless 'em, have their hands full with more important

deliveries.

March

24th 2020

South Florida's broiling summer is approaching and I'm looking for ways

to mitigate the effects in the BillyBob Shop. I hadn't given much

thought to a dehumidifier because the shop is not insulated and the two

12'

x 12' overhead doors are big air leaks. There is a 24" diameter hole up

high in the rear wall with a broken fan in it as well.

March

24th 2020

South Florida's broiling summer is approaching and I'm looking for ways

to mitigate the effects in the BillyBob Shop. I hadn't given much

thought to a dehumidifier because the shop is not insulated and the two

12'

x 12' overhead doors are big air leaks. There is a 24" diameter hole up

high in the rear wall with a broken fan in it as well.

My friend, Dave Sexton, has a free-standing shop comparable to the BillyBob Shop and he reports that a dehumidifier drys it considerably, making it more comfortable for summer work. Based on Dave's report, I purchased a heavy-duty dehumidifier. I got one rated for double the area of the BillyBob Shop because of the sixteen foot ceiling height.

Set it up in the BillyBob Shop over the weekend and started it up. Within three hours, the humidity had dropped from 58% to 46% and the water container had topped out at 1.8 gallons, at which point, it turned itself off.

The next day, I searched the shop and found a garden hose I

had originally gotten, way back, to drain a water bed and hooked it up

to the

dehumidifier to provide continuous drainage. It's running continuously

now. Lowest observed humidity in the shop has been 42% thus far. I can

feel a difference and it's too early to tell, but I believe it's

relieving the heat rash on my forearms somewhat.

March

26th 2020

Started block sanding the Eastwood Contour aluminum reinforced

filler with 36 grit paper. It's tedjus work. I just have to keep

slogging away at it. I made it worse by using too much hardener in my

first batch and then waiting two days to start sanding it down. Beer of

the day was Hamburg Brewing Company's Small Town Belgian Style Saison

Ale.

March

26th 2020

Started block sanding the Eastwood Contour aluminum reinforced

filler with 36 grit paper. It's tedjus work. I just have to keep

slogging away at it. I made it worse by using too much hardener in my

first batch and then waiting two days to start sanding it down. Beer of

the day was Hamburg Brewing Company's Small Town Belgian Style Saison

Ale.

April

3rd 2020 Found additional dents in the dust

that I'd missed before. Gave the additional dents the

Scotchbrite cookie

treatment. Cleaned and then wiped the top with PRE paint prep and

applied a second layer of mud to all the low areas.

Then it was back to the 36 grit paper.

April

3rd 2020 Found additional dents in the dust

that I'd missed before. Gave the additional dents the

Scotchbrite cookie

treatment. Cleaned and then wiped the top with PRE paint prep and

applied a second layer of mud to all the low areas.

Then it was back to the 36 grit paper.

Found more dents while block sanding. Took to marking them with a sharpie so I don't miss them with the third, and I hope last, layer of mud.

The work is slow and summer conditions are almost here in

South Florida. I've adjusted my schedule to compensate. I run the

dehumidifier during the day when I'm at the Krash Kubicle. I get a

couple of hours in after work and, In the middle of the nite when I

first

awake, I put in another hour or two before heading back to the office.

Beer of the day was Uinta Brewing Co's Yard Sale Winter Lager.

April

6th 2020 Applied a third and fourth layer of filler

and sanded with 36 grit until I ran out and switched to 40 grit. Was

pretty close at this point so it was sanded again with 80 grit,

followed up by a final sanding with 180 grit.

April

6th 2020 Applied a third and fourth layer of filler

and sanded with 36 grit until I ran out and switched to 40 grit. Was

pretty close at this point so it was sanded again with 80 grit,

followed up by a final sanding with 180 grit.

Washed the cab top with fresh water, Masked areas not to be painted, and PRE paint prepped bare metal areas to give them a coat of Rustoleum primer. The primer spray bomb had a mis-behaving nozzle so there are drips, runs and sags to clean up.

The International Red Rustoleum farm equipment paint will be

rolled on so surrounding areas where a roller doesn't work were

spray-bombed. Beer of the day was Hamburg Brewing Company's OMS Oatmeal

Milk Stout.

April

8th 2020

Continued the shop reorganization exercise with the right side of my

sit

down work bench and file cabinet. Out in the open were another X-Acto

knife set, two pair of magnifying glass visors and a loupe magnifier.

That's right, I can't see worth spit anymore.

April

8th 2020

Continued the shop reorganization exercise with the right side of my

sit

down work bench and file cabinet. Out in the open were another X-Acto

knife set, two pair of magnifying glass visors and a loupe magnifier.

That's right, I can't see worth spit anymore.

File cabinet top drawer holds vehicle records, receipts and tool manuals. Bottom drawer has two-sided poster tape, 2 sizes of ziplock baggies and performance decals. The drawer in the bench is junk drawer with matches, pens, scissors and razor blades.

Below, right to left, is an Innova canOBD2 scan tool and an Astroline four ton Body and Frame Kit. The first metal tool box contains a whetstone, 2 guide rods, hacksaw and blades, 2 file handles, 2 file cleaners, staple gun and staples, pop rivet tool, 2 claw hammers, 4 drill bit sets steel and masonry, 2 packs of utility knife blades, battery engraving tool, stud finder, screw driver twist bit set, and assorted drill bits.

Metal box two had 2 putty knives steel and plastic, a long guide rod, 2 tin shears and trowel all rusty, pipe wrench, grout rake, assorted open end SAE wrenches, assorted screwdrivers, scrapers and a plastic pry tool.

Metal box three contains a Black and Decker finishing sander, a Black and Decker 3/8" drill motor, 2 small caulking guns, wire nut assortment, misc screw assortment, assorted drill bits and sockets, a welding striker, assorted screwdrivers and allen wrenches, miniature claw hammer, battery engraver and a feeler gauge.

April

10th 2020

Sanded the primer drips, runs and sags with 240 grit. Went over the

rest of the top with a scotchbrite pad, wiped it down with mineral

spirits and

ran a tack cloth over it.

April

10th 2020

Sanded the primer drips, runs and sags with 240 grit. Went over the

rest of the top with a scotchbrite pad, wiped it down with mineral

spirits and

ran a tack cloth over it.

Mixed paint for the first time thinning with about 20% mineral

spirits. Looks like I got that right since there was no paint left

over. The foam rollers are not meant for this kind of paint. Two of

them separated from their spindles. Thankfully, neither one bounced off

my office jeans on their way to the floor. I was also loading up the

rollers with too much paint. Got to fine tune my technique. All in all,

the first coat turned out better than I thought it would.

107 degree heat index today. The dehumidifier helped a lot.

Beer of the day was Uinta Brewing's BABA Black Lager.

| < Back

to Intro |

You can email me at ![]() webmaster@laroke.com

webmaster@laroke.com

Issued Friday April 10, 2020

copyright © 2008-2020 Larry R. Kephart all rights reserved

| | LRK Home | | Bio Info | | Krash Khronicles | | LAROKE | |

| | BettyLou | | BillyBob's Garage | | Rat Patrol | | Deerslayer | | Elvira | |

| | Land of the Free and Home of the Brave | |

| | Keppylou's Art | | WWI Soldier's Diary | |